Ignitec’s Rapid Prototyping Service: Quality and Efficiency in One

Experience the benefit of Ignitec’s Rapid Prototyping Service: fast, affordable, and high-quality prototypes delivered by experts. Our service is designed to address your need for efficient, high-performance prototyping, ensuring your idea comes to life with speed and precision.

The Ignitec advantage

With more than a decade’s experience, our Rapid Prototyping Service offers unparalleled speed and quality, moving swiftly from concept to complete prototype.

Why use our Rapid Prototyping Service?

- Quality and Efficiency: We offer high-quality prototypes within a short timeframe

- Cost-effectiveness: Get the best value for your money with our competitive pricing

- Expert Guidance: Benefit from our expertise to understand your prototyping options

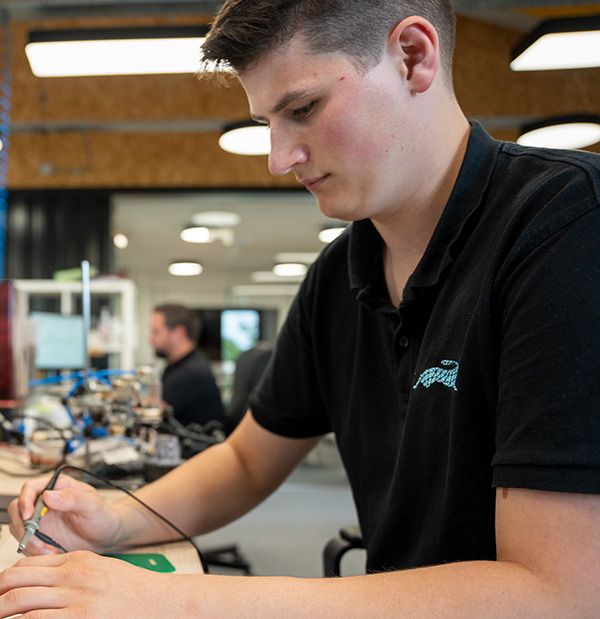

Rapid Prototyping Expertise

Ignitec, established in 2013, has been at the forefront of product development for more than a decade. Our extensive expertise enables rapid iterations, significantly speeding up the product development process.

State-of-the-art Facilities

Our advanced on-site facilities feature six 3D printers, including four Stratasys industrial machines, a large laser cutter, an electronics lab, and our own dedicated workshop for prototyping.

Integrated Solutions

We offer a fully integrated solution. Our Rapid Prototyping Service oversees the full process, from initial concept to complete prototype. No need to juggle multiple external services – we’ve got you covered.

Resource Conservation

It’s about simplifying your journey, conserving your valuable resources, and delivering a prototype that truly meets your vision. We know the challenges of developing a product: the need for substantial resources, the complexity, and the time. But with our Rapid Prototyping Service, these worries become a thing of the past.

Our Promise

Ignitec’s Rapid Prototyping Service isn’t just about speed. It’s about quality, affordability, and expert guidance. It’s about ensuring your idea comes to life with the best possible value for your investment.

Turn

The face of timeless smart-home control

CASE STUDY | INTERNET OF THINGS

MiMu

Creating and performing music through movement and gesture

CASE STUDY | WEARABLE TECHNOLOGY

Audio Wings

Smart headphones for music lovers on the move

CASE STUDY | WEARABLE TECHNOLOGY

Find Out How We Can Help – Contact Us for Expert Guidance on Your Next Project

Years established

Projects delivered

Clients served

Get started

Our expert team is here to help with all of your electronic design, software and mechanical design challenges. Get in touch with us now for more information and a free review of your requirements.