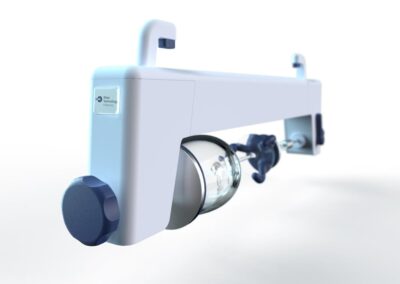

Forensic autorotator

An innovative concept for accelerating the process of exposing fingerprints on cylindrical objects such as bottles and glasses recovered from crime scenes.

- Concept design

- Mechanical Design

- Mechanical prototypes

- Design for manufacture

- Design for assembly

- Design for low volume

- Mechanical engineering

- Product renderings

Ignitec rapidly developed a new concept that could be manufactured in low to medium volumes using existing manufacturing capabilities with the flexibility to scale volumes as demand grew.

West Technology Systems is a UK-based company that is a leading manufacturer of vacuum metal deposition chambers for latent finger print development. The process of vacuum metal deposition allows for the exposure of finger prints on a wide range of objects, from paper to metal, which are recovered from crime scenes.

Our client was facing a challenge when it came to exposing finger prints on cylindrical objects such as drinking glasses and glass bottles. This required the objects to be removed from the chamber and rotated manually, which was time-consuming and posed the risk of contamination. To overcome this challenge, West Technology systems approached Ignitec to develop an electromechanical accessory for their large exposure chambers that would automatically rotate the objects and aid in the exposure of finger prints all the way around the outside.

Ignitec was quick to respond to the challenge and rapidly developed a new concept that could be manufactured in low to medium volumes with the flexibility to scale volumes. The accessory was designed to be assembled using existing tools and the in-house workforce. This made the manufacturing process more efficient and cost-effective, without sacrificing the quality of the final product.

The new electromechanical accessory provided our client with a significant advantage, allowing them to expose finger prints on cylindrical objects more quickly and with greater accuracy. It eliminated the need to remove specimens from the chamber, reducing the risk of contamination, and improving overall efficiency in the forensic analysis process.