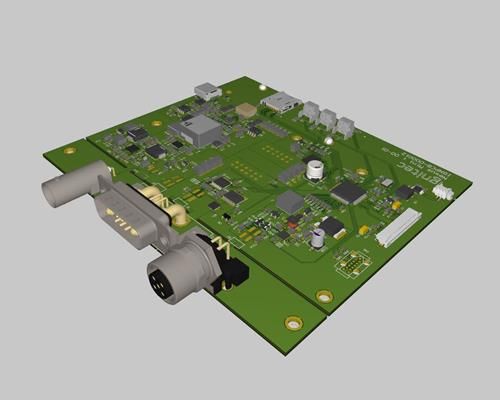

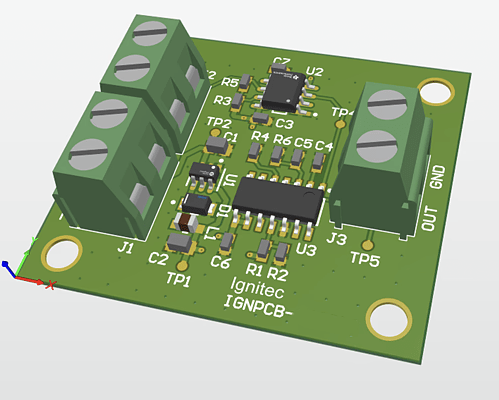

Innovative Electronic Design Services, From Concept to Production

Designing Custom Electronics Since 2013

Book a free consultation

We will send you a signed NDA and an invitation to book a free consultation.

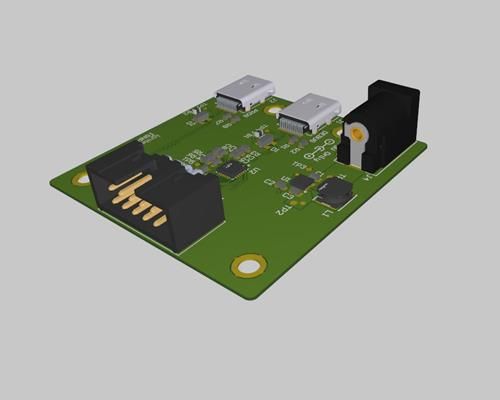

Full-Service Electronic Design—From Initial Concept to Final Product

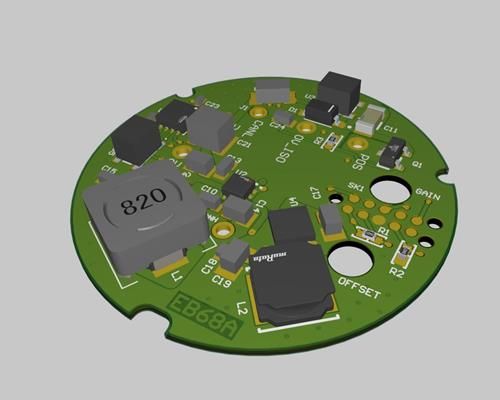

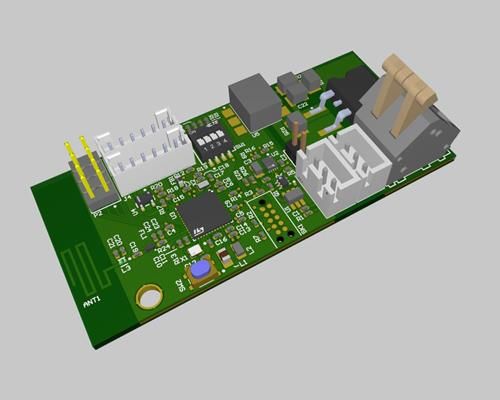

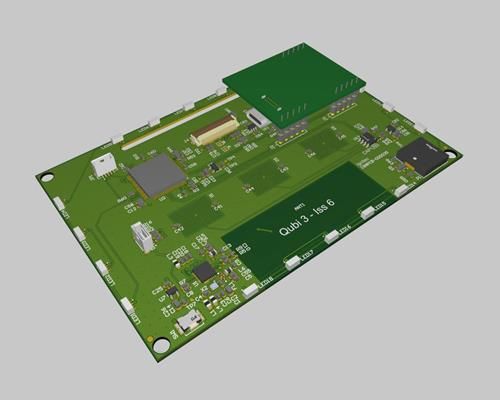

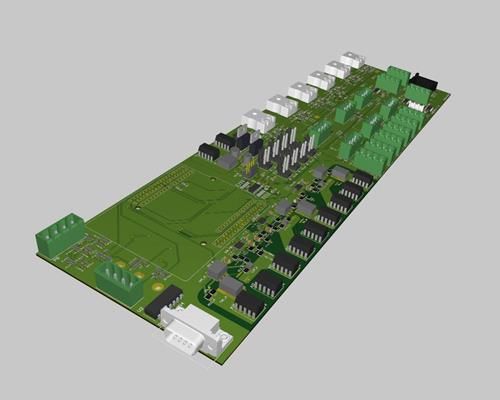

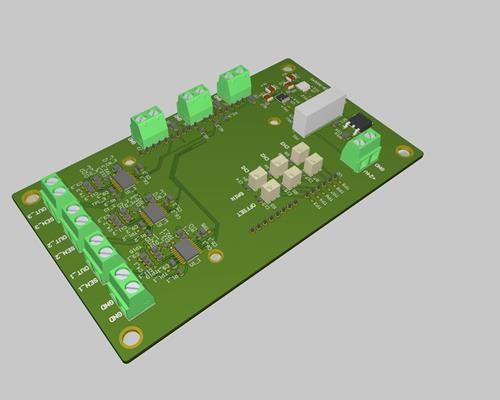

PCB Design & Layout:

High-quality PCB designs that optimise performance and reliability.

Simulation & Testing:

Advanced simulations to validate designs and reduce development risks.

Compliance & Certification:

Expertise in navigating EMC, CE, and RoHS standards for a smooth approval process.

Manufacturing & Supplier Network:

Production-ready designs backed by our trusted global manufacturing partners.

Trusted by Clients Worldwide for 5-Star Electronic Design

Book a free consultation

We will send you a signed NDA and an invitation to book a free consultation.

Our Expert UK-Based Electronic Design Team Is Ready to Drive Your Project Forward

UK-Based Team:

Work directly with our skilled UK engineers every step of the way.

Fast Turnaround:

Rapid design cycles to keep your project moving forward swiftly.

Deep Expertise:

Over a decade of experience in complex electronics design.

Trusted & 5-Star Rated:

Proven track record with excellent reviews and happy clients.

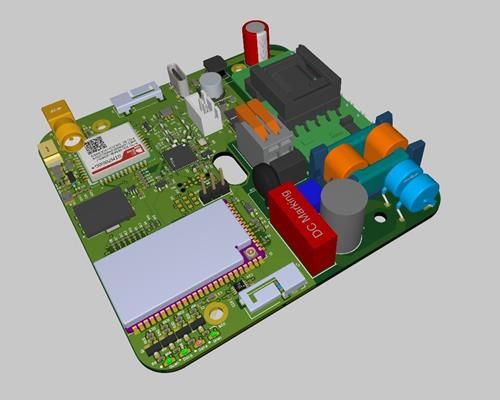

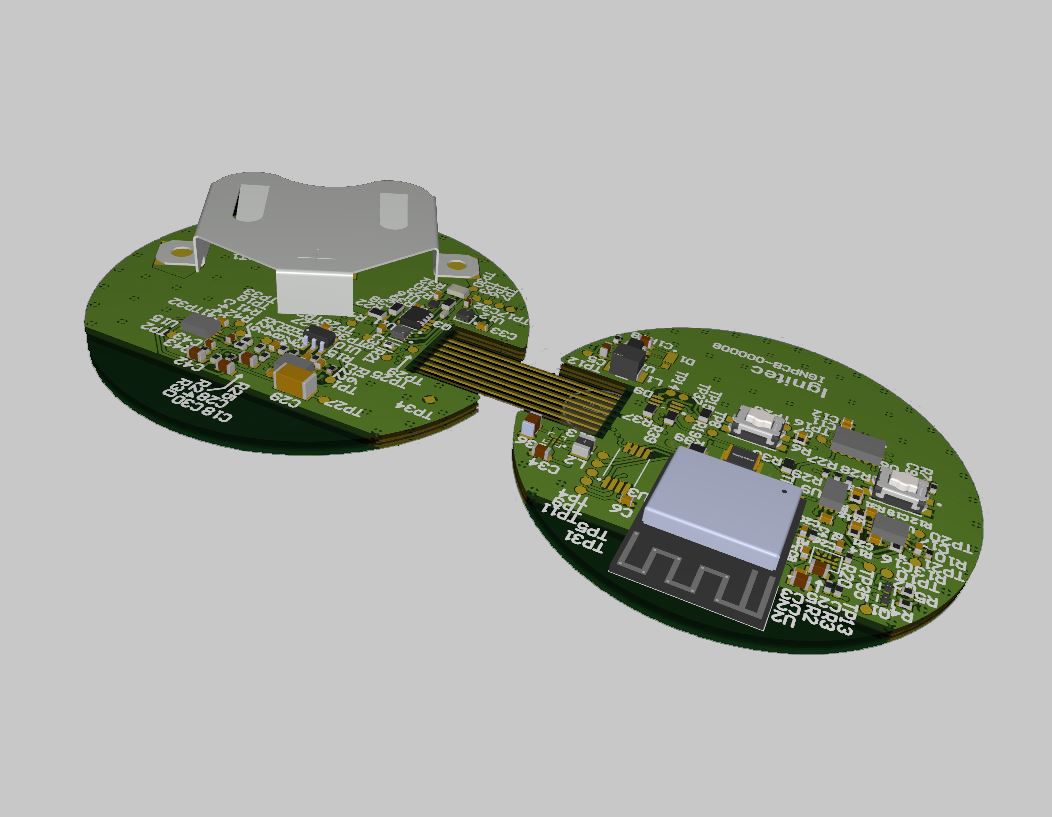

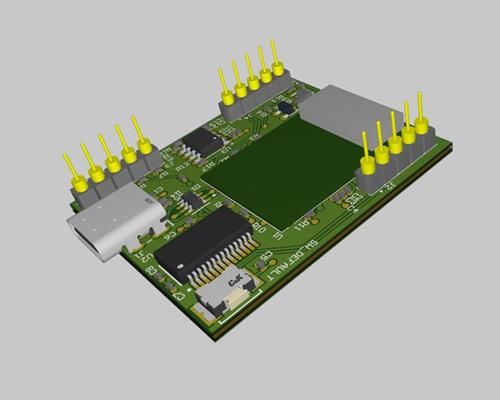

Explore Our Clients’ Success Stories and See the Results

Controller for subsea exploration designed and delivered in low-volume batches on a fast turnaround.

CASE STUDY | Marine, Subsea, Energy

MESH GLOBAL

Custom water level sensor for monitoring arctic glacial melt to support world-class research institution.

CASE STUDY | Marine, Monitoring

AARHUS UNIVERSITY

Custom NFC reader, writer and tag emulator designed to capture ticket and pass information at venues.

CASE STUDY | IoT, Wireless

SMART IMPACT

Expert Solutions for Highly Regulated Industries

Aerospace

Defence

Medical

IoT

Automotive

Subsea

Trusted by Global Leaders

Book your free electronic design consultation

Talk to an expert about your electronic design requirements now. Our UK based electronic design team are ready to discuss your requirements, answer your questions and review your designs. Get free, expert advice via an introductory video call now.

What PCB design software do you use?

We use Altium Designer for most of our PCB design projects. We can work with files generated by most other software packages including KiCad, Proteus, Eagle etc. Book a Free Consultation if you have questions regarding a particular design software package or file format.

Will you sign an Non-Disclosure Agreement (NDA)?

Yes, Book a Free Consultation with us and we will send you a signed, legally binding NDA before the call. You may also send us your own NDA for signing once you have booked the consultation.

Our previous electronic engineer has left and I need to make a change to a design, can you help?

Yes, Book a Free Consultation and one of our design experts will review your design for free.

I have an old piece of hardware which need updating and no design files, can you help?

Yes, Book a Free Consultation and we can discuss options for updating your design.

I have a design and some of the parts have gone obsolete, can you help?

Yes, Book a Free Consultation and we can discuss options for sourcing new parts and updating your design.

What types of electronic design services do you offer?

We offer comprehensive services including circuit design, schematic capture, PCB layout, prototyping, manufacturing, testing and software integration tailored to industries like medical, automotive, and IoT. Book a Free Consultation to discuss your specific requirements with us.

How quickly can you start working on my project?

We can begin design work on your project as soon as we understand your requirements, often starting within a few days of initial contact. Book a Free Consultation with us and we can give you an exact answer as well as expected time to complete your project.

Do you handle manufacturing as well as design?

Yes, we provide full manufacturing services through our global network, ensuring your product is produced efficiently and to high standards. Book a Free Consultation to discuss your specific manufacturing requirements.

Can you assist with product compliance and certifications?

Absolutely, we can guide you through the entire compliance and certification process to meet industry standards and regulatory requirements. We work with third party test-houses to deliver certified products. Book a Free Consultation to find out more.

Can you help with software and firmware too?

Yes, our engineers work closely with you to develop and integrate software and firmware that complements the hardware, ensuring seamless functionality and performance. Book a Free Consultation to discuss your requirements with one of our experts.

What industries do you specialise in for electronic design?

We specialise in electronic design for industries such as Energy, Aerospace, Medical, Automotive, Defence, Marine and IoT, among others. Book a Free Consultation to find out more and discuss your specific requirements with one of our experts.

Can you handle both small and large production volumes?

Yes, our global manufacturing capabilities allow us to scale production to accommodate both small batches (usually 1-2 units minimum) and large-scale runs (>100,000) effectively. Book a Free Consultation to discuss your requirements with one of our experts.

What technologies do you incorporate in your designs?

We work with a range of technologies including all common wireless technologies, FPGA, and microcontrollers, tailored to your project’s needs. Book a Free Consultation with one of our experts to find out more about how we can help with your specific technology.

How do you manage project communication and updates?

We maintain open and regular communication with our clients, providing updates at every stage of the project. We use tools like Basecamp, Jira, GitHub and Azure depending on the project and it’s specific requirements. We often work in teams so these kinds of project management tools help centralise decision making and data management. If you would like to know more about how we work the please Book a Free Consultation.

What support do you offer post-manufacture?

Once your products have been manufactured we will normally test them before shipping them out to you to ensure that everything is fully working as expected. We offer ongoing support packages after manufacturing, including troubleshooting, further iterations, and additional compliance assistance if needed. Book a Free Consultation to find out more about our on-going support packages.

Can you assist with other aspects of my project, such as mechanical design, custom enclosures, and housings?

Yes, we can help with mechanical design, custom enclosures, and housings, providing a comprehensive solution that encompasses all aspects of your product’s physical design. Book a Free Consultation to find out more about our Custom Enclosure Design capabilities.

How long does prototyping and manufacturing take?

Prototyping typically takes 1-2 weeks, though we offer a 24-48 hour fast track option for urgent needs. Manufacturing larger volumes generally takes between 4-6 weeks. Got an urgent manufacturing requirement? Book a Free Consultation to discuss it with a member of our team.

How long does a project take from start to finish?

Typically, projects take between 4 and 12 weeks depending on complexity. We can offer shorter, 2 week sprints for smaller projects such as Proof of Concept prototypes. Larger and more complex projects may extend up to 6 months or more, and these are usually structured in smaller stages of 4-12 weeks each. Book a Free Consultation to discuss your requirements with one of our experts.

I don’t know what my requirements are

No problem! Book a Free Consultation and one of our expert UK based team members will be happy to advise you.

Still have questions?

Book a call with one of our engineering team. We will send you a signed NDA and an invitation to book a free consultation.